Savings:

2,531,772 kWh

$278,490*

$210,360

$253,180 incentive

(capped at project cost of $210,360)

* Estimated Annual Energy Cost Savings is based on a blended rate of $0.11/kWh

Visit peco.com/Business to learn more.

Lavazza, a coffee product manufacturer, upgraded its West Chester, Pennsylvania, production facility’s compressed air system—saving big and gaining incentives to pay for 100% of improvements.

Lavazza works hard to bring delicious coffee straight from the farm to its customers’ mugs — and to do so sustainably. “We have a culture of continuous improvement,” said Lavazza manufacturing engineer Josh Miller. In 2014, major renovations to their manufacturing facilities earned them LEED certification, and the company has worked closely with PECO to make a number of energy efficiency improvements since then, including LED lighting upgrades.

A Compressed Air Energy Drain

Recently, Lavazza addressed a major energy drain: their facility’s compressed air system. These systems are used in many industrial facilities, and Lavazza uses theirs to power certain processes along the production line. Unfortunately, compressed air systems use a lot of energy, and older systems tend to spring leaks, leading to increased energy waste.

Lavazza mainly relies on their compressed air system to generate the nitrogen that keeps their coffee fresh from production to the first sip. Though it’s less expensive than purchasing and transporting liquid nitrogen, producing nitrogen on site is still energy intensive. The compressed air system drove 37% of Lavazza’s energy costs in 2022. Since one of the company’s key values is energy responsibility, reducing that high energy use was a priority.

“It Was a Huge Opportunity”

Using advanced analytics, Miller and Kai Wong, Lavazza’s energy solutions partner at Emergent Energy Solutions, saw an opportunity to upgrade and save. (The two have worked together on past projects, including LED lighting retrofits, to save energy at Lavazza.) “There are so many run-hours on a compressed air system like this,” said Wong, “that even very minor changes can have huge impacts on energy use.”

“It was a huge opportunity for Lavazza to be more responsible with our energy use, and also just reduce our monthly spend on electricity,” said Miller.

Miller and Wong studied the system’s advanced analytics, then planned a series of incremental efforts to reduce energy use.

- Addressing the air compression system’s leaks would plug a major energy drain at its source.

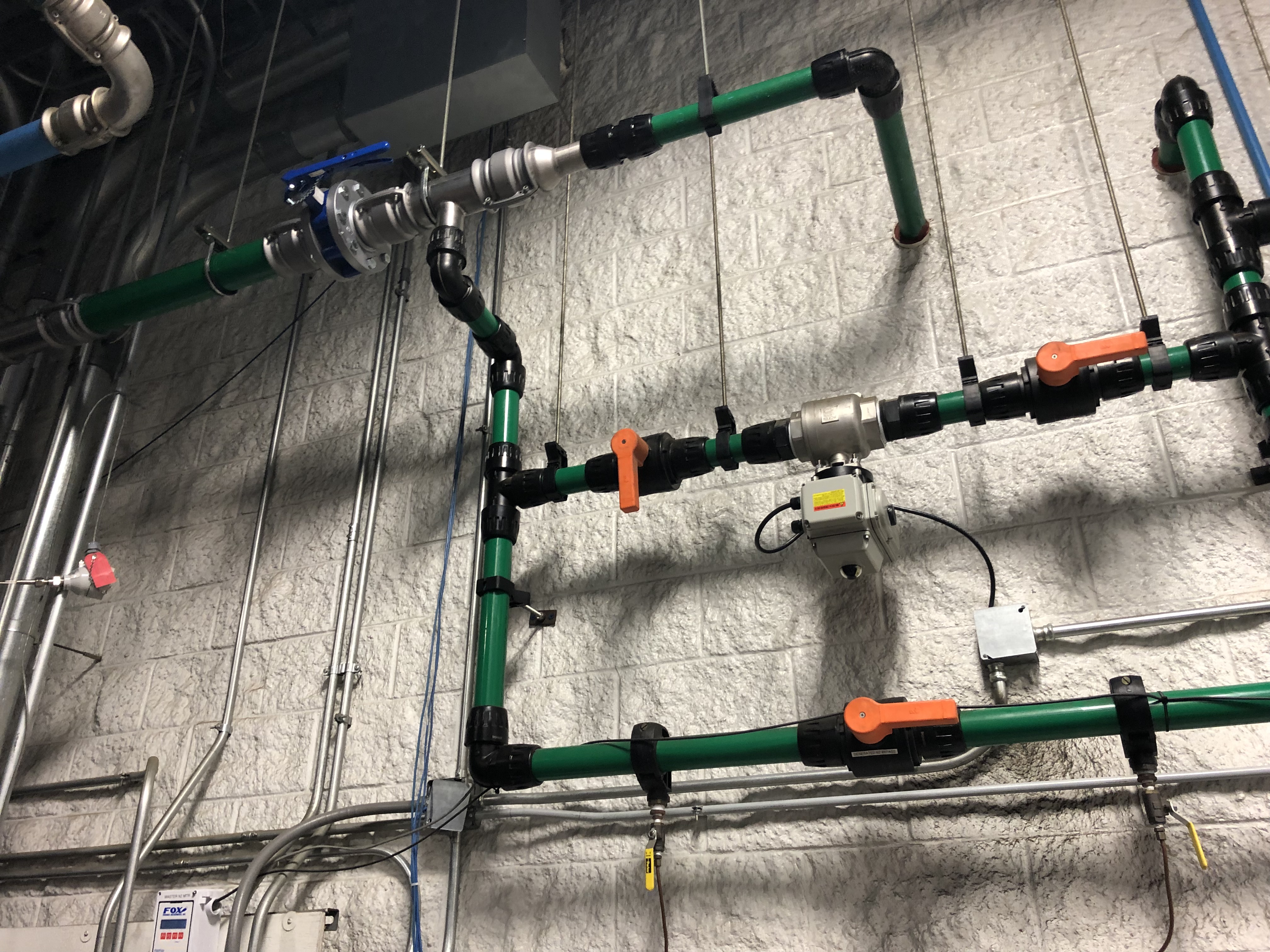

- Repiping with reduced elbows and upsized diameters could improve efficiency.

- Using eco-mode would shut off generators when demand decreased.

Together, these system updates would result in saved energy and require much less maintenance.

Upgrading a vital production system like air compression can be a daunting task. But Miller and Wong pre-planned the installation to minimize disruption to production-line work. Vitally, they needed to continue to supply nitrogen and compressed air to the factory while making the improvements. “For the most part, we were able to work through it and valve off certain areas,” Miller said. Work continued apace during the installation.

Altogether, these changes reduced the total pressure drop in Lavazza’s air and nitrogen compression system by over 5 psi. In energy figures, this is an enormous victory for the company. The improvements will reduce their energy consumption by 2.5 million kWh over the next year, saving over $278,490 on their estimated annual energy cost savings.*

PECO Incentives Make the Project a Financial Success

And how much did Lavazza end up paying for the air and nitrogen compression system improvement? Zero dollars, since the project received $210,360 in incentives, which covered 100% of the project cost.

The PECO incentive helped Lavazza add extra piping and sensor measures to the system for future automation and troubleshooting. “PECO has found a way to make it easier every year to access incentives for energy-saving upgrades,” said Wong.

That ease makes the incentives even more rewarding. “The incentive amount shows how important this project was to PECO,” said Miller. “Obviously it’s important to us and our business, and PECO is an important partner in that.” Improvements complete, Lavazza can use less energy while delivering an excellent product to happy customers. That’s as refreshing as a good cup of joe.

* Estimated Annual Energy Cost Savings is based on a blended rate of $0.11/kWh